azin plast wide-width nylon

One of the widely used products in the field of thermoplastic materials is wide-width nylon film.

These nylon films can be produced in various dimensions and thicknesses.

Different types of wide-width nylon films are extensively used in agriculture, greenhouse applications, and other industries.

The price per kilogram of this nylon film may vary depending on its quality and application. In this article, we aim to explore the types of wide-width nylon films and their applications.

Additionally, the factors influencing the price of wide-width nylon film will also be discussed. Therefore, we recommend staying with us as we delve deeper into the topic.

What is wide nylon?

This nylon is a type of plastic available in various thicknesses, used in large dimensions for covering greenhouses and subsurface plastic cultivation, as well as for covering construction equipment in civil engineering projects.

These nylons can be produced in different shades of dark and light colors.

The transparent type of these nylons protects plants from pathogens. They are typically produced in widths of 2, 4, 6, 8, 10, and 12 meters.

For greenhouses with an area exceeding one hectare, it is advisable to order widths above 12 meters.

Generally, these nylons are primarily used in the agricultural and construction industries.

In plastic manufacturing plants, the price of this nylon is determined based on its quality and then introduced to the market. We will briefly mention each of these nylons later.

The capability to produce wide plastic sheets was not feasible until recent decades.

This limitation caused irreparable damages. With the production of this nylon, industrialists, farmers, and other professionals across various sectors have been able to meet their needs.

The per-kilogram price of this nylon is highly cost-effective given its functionality.

نایلون عریض آذین پلاست

Wide nylon types

Wide nylon films come in various types depending on their intended use.

These films are available in the market in two colors: transparent and black. The production of wide nylon films can range from single-layer to multi-layer, with their thickness adjustable between 150 to 500 microns.

Single-layer nylon is typically produced with greater thickness compared to multi-layer nylon.

The price of single-layer wide nylon is more economical due to its simpler production process and raw materials.

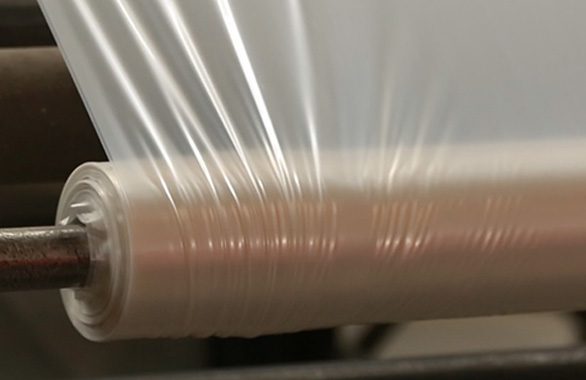

In the video we have prepared for you, dear viewers, you can observe the production of wide nylon at Azin Plastic Company.

Wide nylon also includes the following types, which you will learn more about in the following sections:

Agricultural wide nylon

Construction wide nylon

Greenhouse wide nylon

Agricultural wide nylon

As mentioned, one of the applications of wide nylon is in the agricultural industry.

In agriculture, these nylons are used for cultivating greenhouse products during cold seasons.

Agricultural wide nylon is highly effective in protecting plants due to its UV-resistant, antiviral, and antibacterial properties.

Depending on the type and area under cultivation, you can order and purchase wide nylon with the appropriate width and thickness.

Agricultural wide nylon comes in various models, which you can view on the relevant page.

Construction wide nylon

خرید نایلون عریض آذین پلاستWide nylon is extensively used in construction and civil engineering projects.

خرید نایلون عریض آذین پلاستWide nylon is extensively used in construction and civil engineering projects.

Sometimes, in unfinished buildings, these nylon sheets are used as covers to protect the structure, equipment, and construction materials.

To install wide nylon sheets on buildings, sturdy metal scaffolding with appropriate fasteners must be used.

Additionally, these nylon sheets are widely used as coverings in flooring and roofing to prevent cement and moisture penetration.

Price per meter of plastic

Due to currency fluctuations, the price of this nylon varies daily.

However, in general, factors affecting the price of wide plastic include: the customer’s order quantity (the larger the quantity, the more cost-effective the final price), the number of layers requested by the customer, additives added to the nylon, and similar considerations. The price per meter of plastic, based on the mentioned features and varying widths, is estimated to start from 80 tomans per meter and above.

Features of multi-layered wide nylon

These nylon sheets have a longer lifespan due to their higher strength and durability.

Multi-layered nylon sheets, thanks to the UV-resistant additive compounds used in them, prevent damage to plants under direct sunlight.

These types of nylon sheets also prevent water vapor condensation on roofs. This multi-layered nylon is available in widths ranging from 1 meter to 18 meters.

The price of this type of nylon is determined per kilogram based on its weight and is suitable given its utility volume.

Applications of wide nylon

This nylon is used in various industrial and household applications. These nylon films are widely used in agriculture, greenhouses, and mulching.

In agriculture, transparent nylon is used to allow light transmission into the environment, promoting faster crop growth.

This type of nylon is also commonly used for roofing in mushroom cultivation centers. UV-resistant wide nylon is used in greenhouses to protect greenhouse plants.

The high strength and durability of wide nylon films make them suitable for civil engineering and construction purposes, such as foundations and other applications.

In the livestock industry, these nylon films can be used to create farming equipment.

Price of Wide Nylon per Kilogram

The price of nylon per kilogram and the price of thick plastic per meter may vary depending on the quality, thickness, and whether the nylon is multi-layered.

Generally, the price of these nylon films is calculated based on weight, i.e., per kilogram. Approximately, one kilogram of nylon equals five square meters.

This figure may vary slightly depending on the thickness of the nylon. Therefore, the price per kilogram of this type of nylon changes based on the type of wide plastic.

The price per kilogram of nylon is also estimated based on the manufacturing brand. The more reputable the brand and the higher the quality of its products, the more expensive they are. Therefore, to get the price of high-quality nylon per kilogram, contact us.

Price of Nylon at the Factory

Keep in mind that buying directly from the factory can be beneficial for you. This is because many intermediaries appear between the buyer and the seller, and purchasing from them significantly increases the final price of the nylon.

Thus, buying directly from the factory not only ensures authenticity but also reduces the price of the nylon.

Enhancing the Properties of Wide Nylon with Additives

To enhance the durability and lifespan of this type of nylon, UV-resistant additives are used in the raw material composition. Another additive employed in this nylon is IR (Infrared Absorber), which helps regulate greenhouse temperatures, maintaining a balanced climate during both day and night.

Additionally, Anti-Static additives prevent the accumulation of static electricity, reducing dust buildup on greenhouse plants. Anti-Fog additives minimize condensation inside the greenhouse, protecting plants from sunburn caused by water droplets focusing sunlight.

Summary

Wide-width nylon is one of the most versatile plastics used in agriculture and construction industries.

This type of nylon is utilized in greenhouse construction, mushroom farming centers, and more. Thanks to its specialized properties, it helps protect greenhouse plants from viruses and bacteria.

The nylon is available in different layers, thicknesses, and widths. Generally, multi-layered nylon films offer greater strength, durability, and longevity compared to single-layer variants.

Another key point mentioned earlier is that the price of this nylon is determined by weight, thickness, and quality. In other words, the price per kilogram depends on the current market rate for nylon.